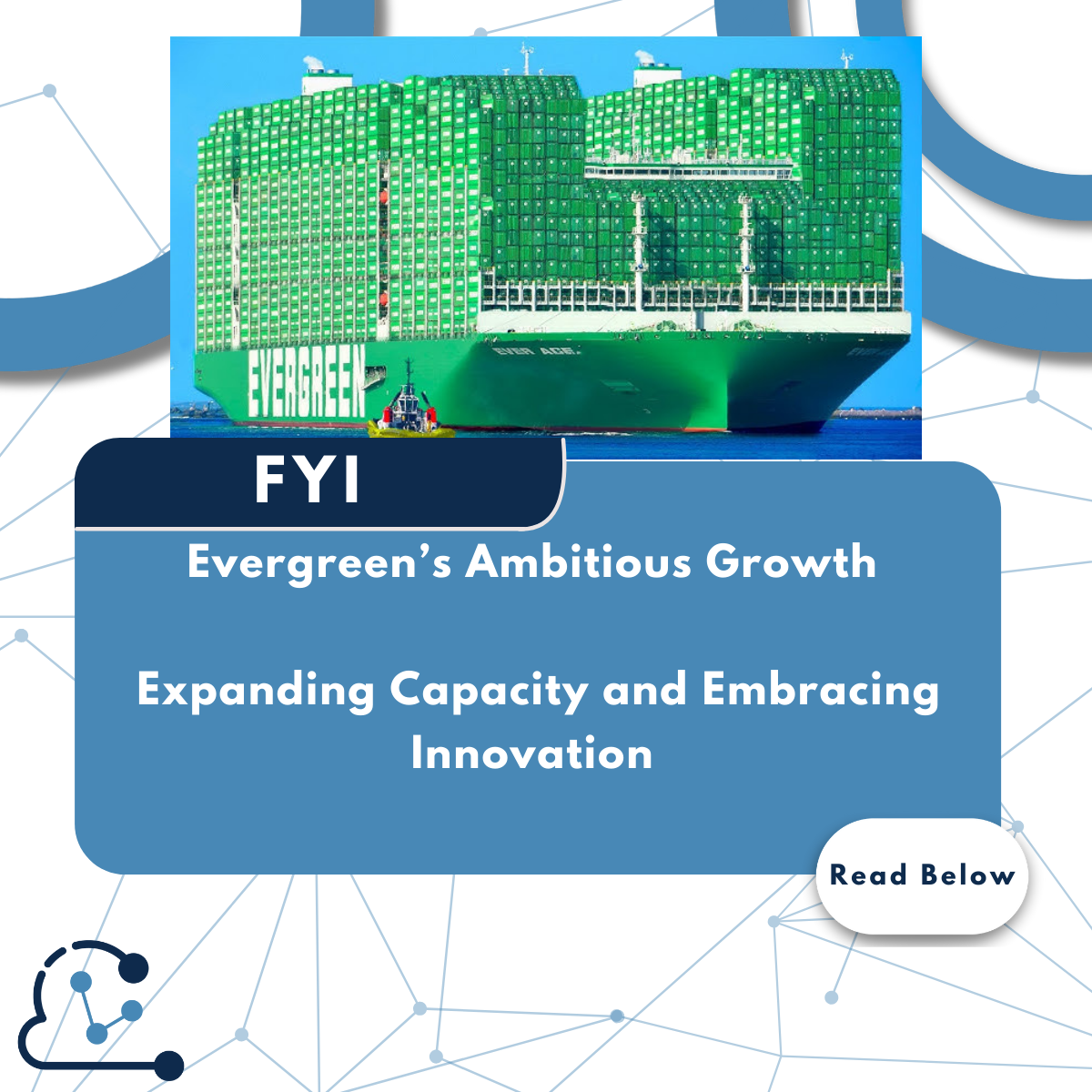

Taiwanese shipping giant Evergreen has made waves in the logistics industry by announcing a massive order for 60,500 new containers, valued at nearly $187 million. The latest filings to the Taiwan Stock Exchange detail that 23,000 containers will be produced by CXIC Group, 21,000 by Guangdong Fuwa Equipment Manufacturing, and 16,500 by Dong Fang International, a subsidiary of Cosco Shipping Development.

This marks Evergreen’s second major capital investment of the year, building on its $348 million order in June for six 2,400 TEU methanol dual-fuelled ships from CSSC Huangpu Wenchong Shipbuilding and 50,000 containers from top Chinese manufacturers, including Dong Fang and China International Marine Containers, at a cost of $162 million.

Adding to its forward momentum, Evergreen recently sought quotes from major shipbuilders for 11 methanol dual-fuelled 24,000 TEU ultra-large container vessels, demonstrating its commitment to sustainable shipping solutions.

Responding to Challenges: Growth Amid a Supply Chain Crisis

The timing of these investments is critical. Evergreen has linked its increasing container inventory to its expanding fleet. With the Red Sea crisis disrupting equipment supply chains and driving container freight rates to record highs, container manufacturers—primarily in China—are operating at full capacity, with many booked out until year-end. This highlights the urgent need for resilience in global shipping operations.

Evergreen’s financial results reflect its ability to thrive amidst these challenges. In the first nine months of 2024, the company reported net profits tripling year-over-year to $3.5 billion, driven by 68% revenue growth to $11 billion.

A Technological Leap Forward

On Friday, Evergreen chairman Chang Yen-I, alongside Taiwan’s transport minister and Kaohsiung officials, officially inaugurated Kaohsiung port’s Terminal 7, Taiwan’s first fully automated container terminal. Built over four years at a cost of $1 billion (with the government investing $642 million), the terminal spans 149 hectares along 2.4km of coastline and features five deepwater berths capable of accommodating four 24,000 TEU vessels simultaneously. With an annual processing capacity of 4.5 million TEU, this state-of-the-art facility will serve as Evergreen’s strategic home base in Kaohsiung.

A Call for Greater Supply Chain Visibility

As Evergreen scales its operations and invests in sustainability, the global shipping industry faces growing complexities. The Red Sea crisis and fluctuating freight rates underline the need for real-time supply chain visibility. Implementing advanced software solutions can provide Beneficial Cargo Owners (BCOs) and Logistics Service Providers (LSPs) with critical data insights, enabling them to make informed decisions that mitigate risks, optimise operations, and adapt to market disruptions.

The integration of such technologies is no longer optional—it’s essential for building resilient and sustainable supply chains. With climate impacts and market volatility reshaping global trade, real-time visibility empowers stakeholders to address both environmental challenges and operational inefficiencies effectively.

Evergreen’s strategic investments signal an exciting future for shipping, but they also highlight the industry’s pressing need for innovation—not just in fleet and terminal upgrades but also in how we manage and monitor the flow of goods across the globe.